YDL Electrical Pneumatic Lifting High Speed Shear Dispersion Mixer Homogenization Machine

Machine Video

Product Introduction

The shear head adopts a claw and two-way suction structure, which avoids the dead angle and vortex caused by the difficulty of upper material suction. The high-speed rotating rotor produces strong shear force, which makes the shear rate higher and the shear force stronger. Under the centrifugal force generated by the rotor, the material is thrown into the narrow and precise gap between the stator and rotor from the radial direction, and at the same time, it is subject to centrifugal extrusion, impact and other forces, so that the material is fully dispersed, mixed and emulsified.

Note: If it is used on vacuum or pressure vessels, the shear needs to be equipped with corresponding mechanical sealing devices

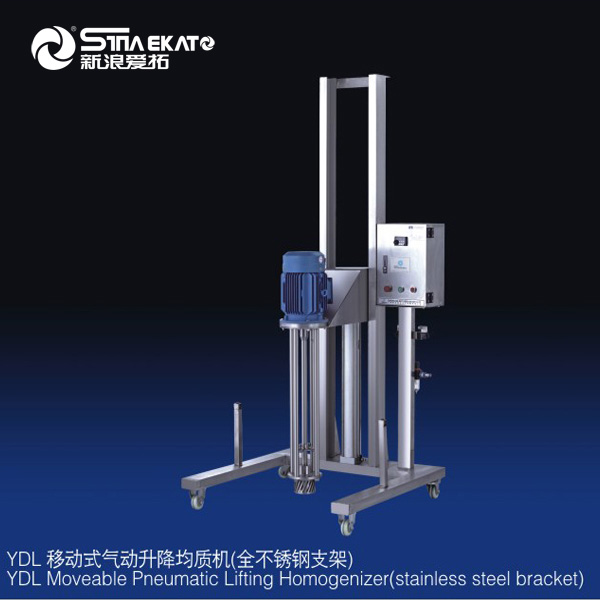

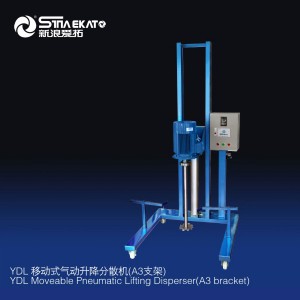

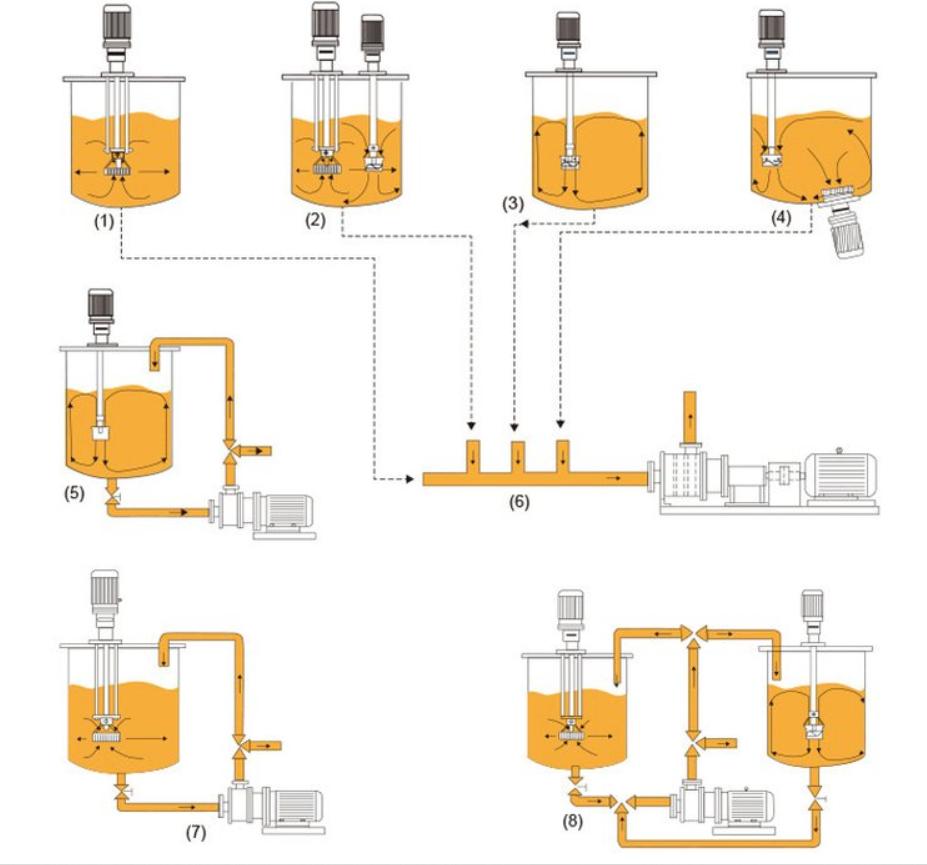

The high speed shear emulsifier integrates the functions of mixing, dispersing, refinement, homogenization, and emulsification. It is usually installed with the kettle body or on a mobile lifter stand or a fixed stand, and is used in conjunction with an open container. High shear emulsifiers are used in emulsification and homogenization production processes in various industries such as food, pharmaceuticals, cosmetics, chemicals, mining, paper making, water treatment, and fine chemicals.

High shear mixers developed by our company are based on the theory of stability of emulsion. The mechanical equipment uses the mechanical energy provided by the system of high shear rotor stators with high speed rotation to blend one phase into the other. Depending on the deformation and rupture of the thick droplets, the thick droplets will break into micro-droplets, ranging from 120nm to 2um. Finally, the liquid droplets are completed as regards a uniform emulsification process.

Actual Photo

Adjustable X stand for make tank stable or move

Homogenizer head (shape can customized)

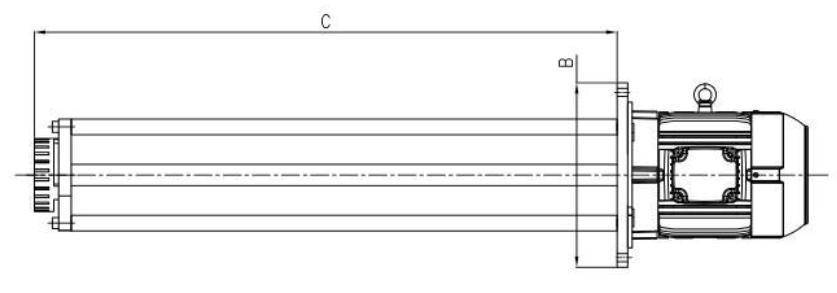

Specification

| Model | Power(Kw) | Speed(r/min) | C(mm) | B(mm) | Processing capacity(L) |

| YDL | 1.5 | 2900 | 430-530 | 270 | 10-70 |

| 2.2 | 2900 | 550-650 | 270 | 50-150 | |

| 4 | 2900 | 750-1000 | 320 | 100-400 | |

| 7.5 | 2900/1450 | 830-1100 | 380 | 200-1000 | |

| 11 | 2900/1450 | 830-1700 | 450 | 300-1500 | |

| 18.5 | 2900/1450 | 1150-1950 | 450 | 500-2000 | |

| 22 | 2900/1450 | 1200-1950 | 485 | 800-2500 | |

| 30 | 2900/1450 | 1350-2700 | 485 | 1000-3500 | |

| 37 | 2900/1450 | 1350-2700 | 485 | 1500-6000 | |

| 55 | 1450 | 1600 | 640 | 2000-10000 | |

| 75 | 1450 | 1600 | 640 | 3000-12000 | |

| 90 | 1450 | 1600 | 640 | 4000-15000 | |

| 110 | 960 | 1600 | 755 | 5000-17000 | |

| 132 | 960 | 2000 | 755 | 6000-18000 | |

| Can be customized | |||||

Relevant Machine

Lab Series