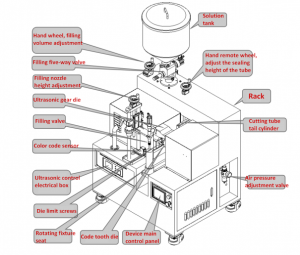

Ultrasonic automatic tube 10-500ml filling and sealing machine

MACHINE LAYOUT

Machine Video

Application

| Power supply | 220v50Hz |

| Air pressure | 0.5Mpa |

| Filling range | 25-250ml |

| Filling accuracy | ±1% |

| Sealing efficiency | 10-15Pcs/Min |

| Sealing diameter | 13-50mm |

| Sealing height | 50~210mm |

| Frequency | 20KHz |

| Power | 2600W |

| Body Materia | SUS 304 |

| Machine weight | 180kgs |

| Machine size | L850*736*1550mm |

Performance & Features

Titanium alloy screw is used at the connection of the equipment mold and transducer

This equipment is equipped with optical eye induction switch, no tube without sealing

This equipment uses C440 stainless steel cutter

Ultrasonic Sealing Technology: The machine utilizes ultrasonic technology for sealing, providing a reliable and efficient sealing process that ensures the integrity of the filled tubes.

Versatility: The machine is designed to handle a variety of cosmetic products, including creams and pastes, making it suitable for a diverse range of cosmetic manufacturing needs.

Semi-Automatic Operation: The semi-automatic nature of the machine allows for manual control, making it suitable for small to medium-scale production while still offering a degree of flexibility and customization.

Precise Filling: The machine is capable of precise and consistent filling, ensuring uniform product distribution within the tubes for a professional finish.

Adjustable Parameters: The machine offers adjustable parameters for filling and sealing, allowing for customization based on specific product requirements and tube sizes.

Easy to Operate: The machine is designed for user-friendly operation, with intuitive controls and a straightforward setup process.

High-Quality Construction: The machine is built with durable materials and components, ensuring reliability and longevity in a production environment.

Compliance with Standards: The machine may be designed to meet industry standards and regulations for cosmetic production, ensuring product quality and safety.

MACHINE CONFIGURATION

| No | Description | Brand | Origin |

| 1 | Ultrasonic system | Electronic automatic frequency tracking control |

|

| 2 | Electric eye | Panasonic | Japan |

| 3 | PLC | Coolmay | China |

| 4 | Relay | Omron | Japan |

| 5 | Touch Screen | Coolmay | China |

| 6 | Inductive switch | Sick | Germany |

| 7 | Cylinder | AirTAC/Xing Chen | China |

| 8 | Solenoid valve | AirTAC | China taiwan |

| 9 | Stepper motor | Just motion | China |

| 10 | Proximity switch | Omron | Japan |

| 11 | Air source processor | AirTAC | China taiwan |

| 12 | Foot switch | Delixi | China |

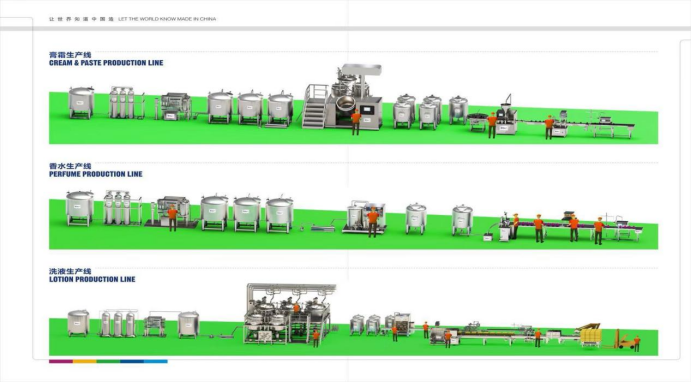

Relevant Machines

We can offer machines for you as following :

(1)Cosmetics cream ,ointment ,skin care lotion ,toothpaste production line

From Bottle washing machine -bottle drying oven -Ro pure water equipment -mixer -filling machine -capping machine -labeling machine -heat shrink film packing machine -inkjet printer -pipe and valve etc

(2)Shampoo,liquid saop ,liquid detergent(for dish and cloth and toilet etc ) ,liquid wash production line

(3)Perfume production line

(4)And other machines ,powder machines ,lab equipment ,and some food and chemical machines

Fully automatic production line

SME-65L Lipstick Machine

Lipstick Filling Machine

YT-10P-5M Lipstick Freeing Tunnel

FAQ

1.Q:Are you factory?

A: Yes,we are a factory with more than 20 years manufacturing experience.Welcome to visit our factory.Only 2 hour fast train from Shanghai Train Station and 30 minutes from Yangzhou Airport.

2.Q: How long is the machine warranty?After warranty, what if we meet problem about the machine?

A: Our warranty is one year.After warranty we still offer you lifetime after-sales services.Anytime you need, we are here to help. If the problem is easy to solve,we will send you the solution by email.If it doesn't work,we will send our engineers to your factory.

3.Q: How can you control the quality before delivery?

A:First,our component/spare parts providers test their products before they offer com- ponents to us, Besides, our quality control team will test machines performance or running speed before shipment.We would like to invite you come to our factory to verify machines yourself. If your schedule is busy we will take a video to record the testing procedure and send the video to you。

4. Q: Are your machines difficult to operate? How do you teach us using the machine?

A: Our machines are fool-style operation design,very easy to operate. Besides,before delivery we will shoot instruction video to introduce machines’ functions and to teach you how to use them. If needed engineers are available to come to your factory to help install machines.test machines and teach your staff to use the machines.

6.Q: Can I come to your factory to observe machine running?

A: Yes, customers are warmly welcome to visit our factory.

7.Q: Can you make the machine according to buyer's request?

A: Yes,OEM is acceptable. Most of our machines are customized design based on cus- tomer's requirements or situation.

Company Profile

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Exhibition Center

Company Profile

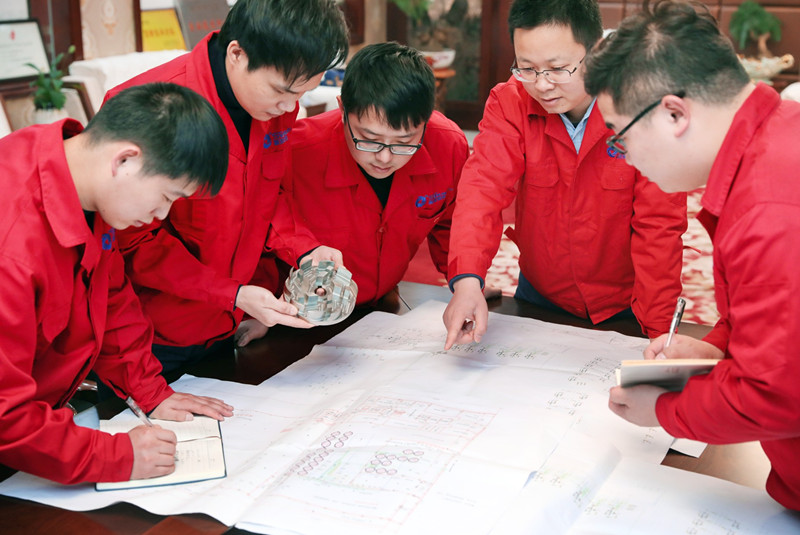

Professional Machine Engineer

Professional Machine Engineer

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Packing and Shipping

Cooperative Customers

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: https://www.sinaekatogroup.com