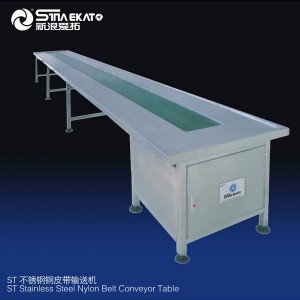

TVF-QZ Splint Type Sachet Packing Machine Cream Lotion Shampoo Conditioner Small Packets Machine

Working Video

Product Introduction

Sachet packing machine widely used to pack milk, soybean milk, sauce, vinegar, yellow wine, all kind of drink with film. The whole process can be accomplished automatically, such as ultraviolet sterilization, bag figuration, date printing, quantitative filling, enveloping, cutting, counting, and so on. The temperature of heat-sealing is controlled automatically, the production is beauty and fastness, the machine adopts stainless steel shell, and the sanitation is guaranteed.it can with glasses cover, ribbon coder and UV sterilizer.

Technical Sheet

| Model | SINAEKATO-Y50 |

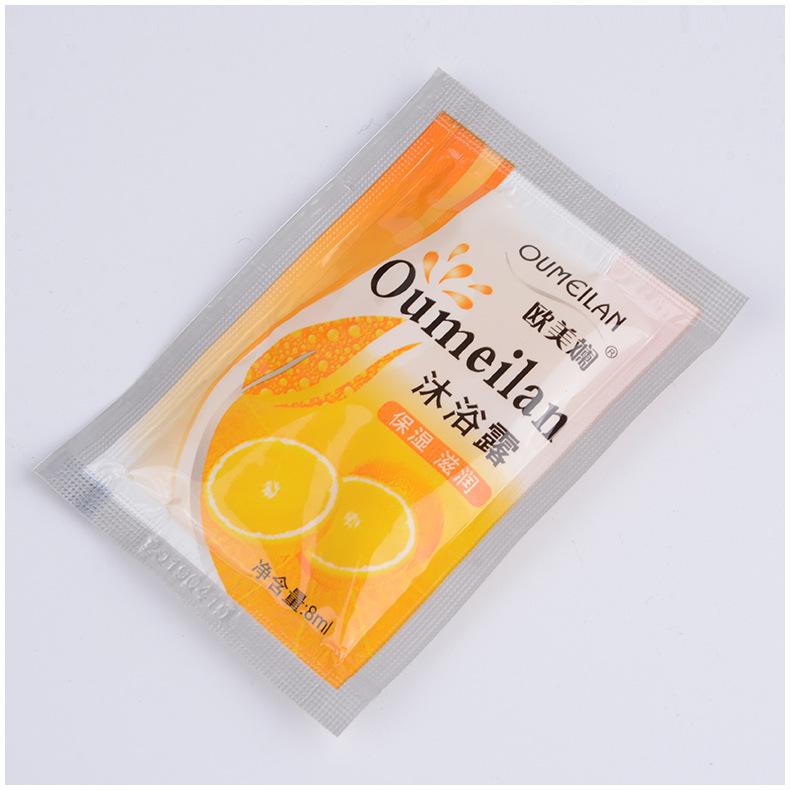

| Material | Shampoo/Conditioner/Cream/Lotion/Perfume/Hand sanitizer |

| Packing weight | 1-50 ML (CAN CUSTOMIZE) |

| Bag size | 90 * 120MM (CAN CUSTOMIZE) |

| Film width | 180MM (CAN CUSTOMIZE) |

| Bag type | 4 sides dots sealing or Other type (CAN CUSTOMIZE) |

| Material discharge way | Piston pump metering; |

| Speed | 20-35 bags/min; |

| Machine dimension | 850 * 1250 * 1500mm; |

| Weight | 260KG; |

| Power | 1.5KW |

| Material contact | Stainless steel 304; |

| Feature | Fully automatic film bag making, metering, filling, sealing, steel press code, cumulative output, finished product output and a series of work. |

| Suitable packing material | Composite bag, such as: OPP+PE/PET+PE/PET+AL+PE/NYLON+PE/PAPER+PE... |

Characteristic

1. Pneumatic control including metering and bag-making, simple operation, less wear parts, reduce parts replacement;

2. Equipment configuration is easy key control, man-machine interface, stable and convenient;

3. Material: the box adopts SUS201, the contact part of the material adopts 304 stainless steel.

4. Use photoelectric accurate positioning to retain the integrity of the pattern. Photoelectric abnormal alarm, three bags of abnormal cursor, automatic stop;

5. Intelligent temperature controller to control the transverse and longitudinal sealing body temperature;

6. It is recommended to use 2 diaphragm pump automatic feeding, automatic feeding of missing material, full material stop feeding, reduce the material and Air contact produces oxidation reaction, and can reduce the number of artificial feeding.

7. The equipment is equipped with casters for easy handling and moving.

Configuration

PLC & Touch Screen: YISI

Temperature control: YUYAO

Relay: YUYAO

Power switch: Schneider

Proximity switch: RUIKE

Step motor: NACHUAN

Photoelectric sensor: JULONG

Air components: Airtac

Packing & Shipping

Lab Series