Steam Jacketed Tank Stainless Steel Mixer Alcohol Gel Shampoo Reactor Shower Gel Agitator Mixer Tank

Product Feature

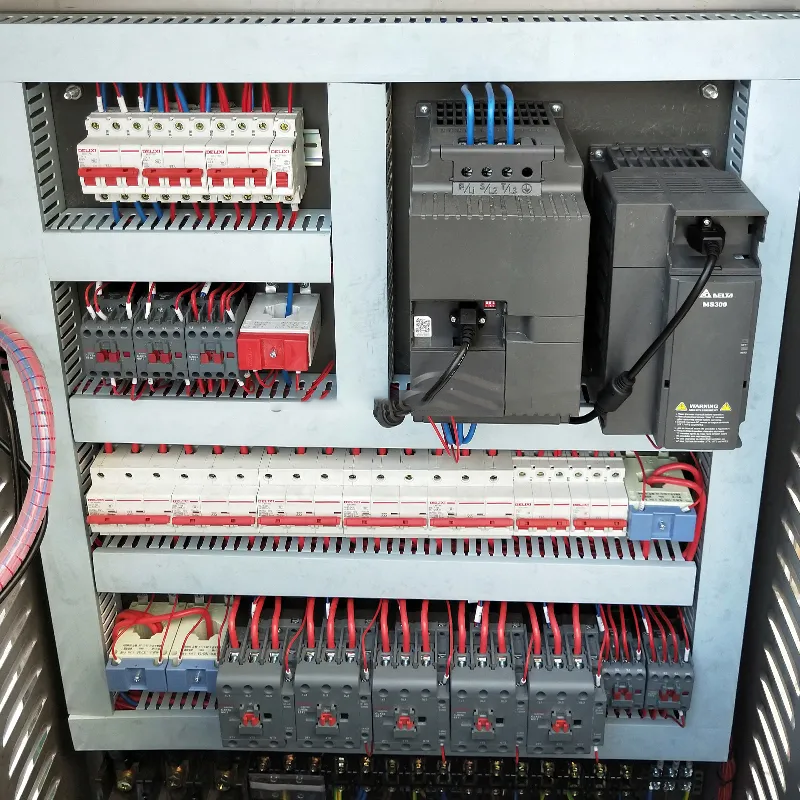

1. The triple mixing adopts the imported frequency inverter for speed adjustment, which can meet different technological demands.

2. The homogenizing structure is made through German technology. The machine adopts the improted double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 3500rpm and the high shearing fineness can reach 0.2-5um.

3. The vacuum defoaming can make the materials meet the requirement of being aseptic . The vacuum materials vacuum sucking can avoid dust.

4. The main boiler lid can adopt lifting system, it is easy to clean and the cleaning effect is more obvious, the main boiler can adopt tilting discharge.

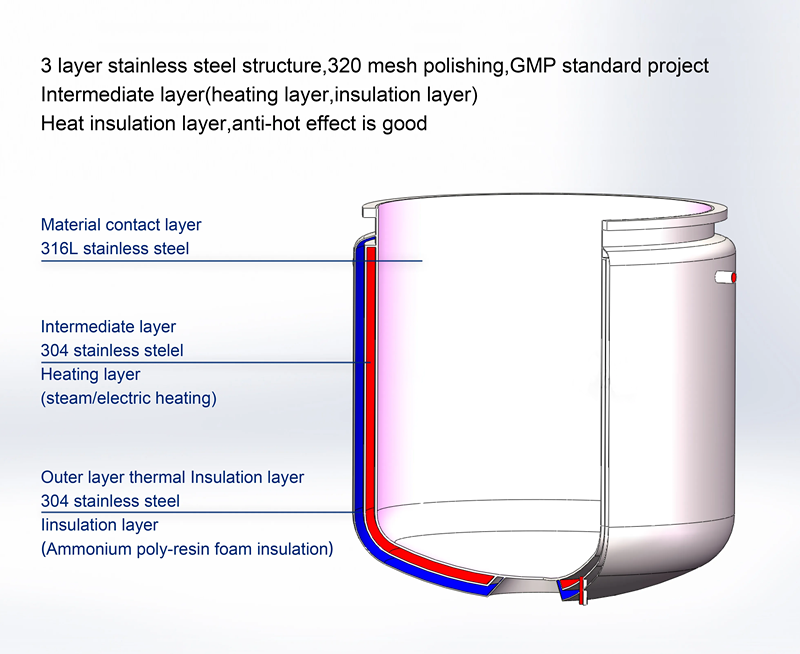

5. The boiler body is welded with 3 layer imported SS plate, tank body and pipes adopts mirror polish which meet the GMP standard.

6. According to process requirement, the tank body can heating and cooling the electric heating.

7. To ensure the stability of whole machine, the machine adopt the imported electric appliances which can meet the international standards.

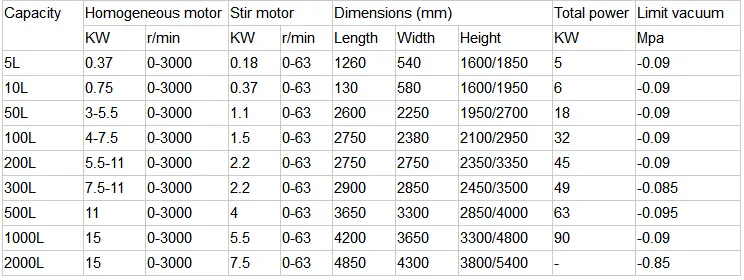

Specification

| Product | Vacuum Homogenizer Emulsifier Cream Lotion Mixing Tank |

| Type | Fixed type |

| Heating Method | Steam or electricity |

| Control | Manual or by touch screen |

| Product Capacity | 50L-2T, customized |

Product Details

Cooperative customers

Customer Comment