Sina Ekato High Speed Fully Automatic Facial Mask Filling And Sealing Machine

Machine Video

Performance & Features

1. Automatic bag feeding, filling, sealing, code printing and outputting

2. The parts that contact materials are all made of stainless steel 316, meeting GMP requirements.

3. Different filling machine are selected according to the nature of materials. The standard configuration is electronic gear pump, and the optional configuration is pneumatic piston pump, which is suitable for filling of facial mask liquids of relatively high viscosity

4. No filling is carried out if there is no bad. No sealing is carried out if there is no bag. The seal is not sticky to the bag.

5. Operation is controlled by PLC+LCD. The equipment parameters, output and error information are clearly seen on the touch screen.

6. Digital display of temperature control.

7. The electric and pneumatic components are all products of international famous brands.

Technical Parameters

|

Model

|

|

|

Action flow

|

Automatic bag feeding,automatic filling,automatic sealing,finished products outputting

|

|

Passage number

|

6(Can control independently)

|

|

Production efficiency

|

7000-7500PCS/H

|

|

Facial mask bag specification

|

Wide95-160mm Length120-220mm Note:Eye masks and other special bag packaging specification can be made to order.

|

|

Standard filling pump

|

Electronic gear pump,accuracy±0.2g

|

|

Power supply

|

Power supply:380V3Ph/50Hz Power7.5KW

|

|

Air pressure

|

0.6Mpa 300L/min

|

|

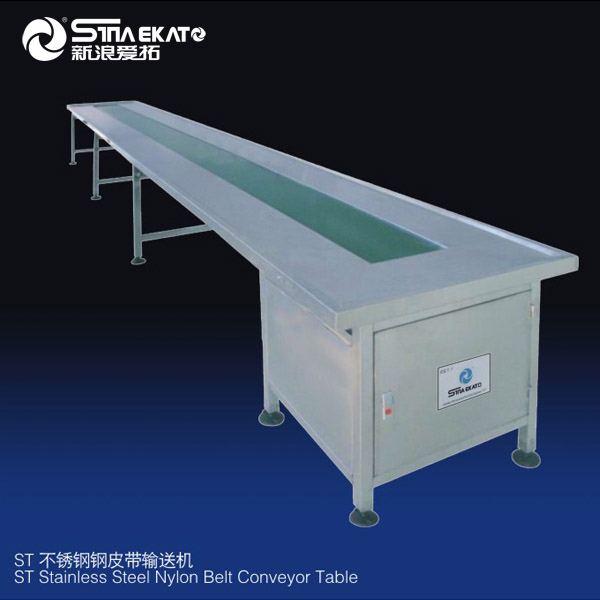

Equipment size

|

L2250*W1050*1720

|

Product Details

Automatic facial mask filling and sealing machine Function is Automatic bag feeding, automatic filling, automatic sealing, coding, finished product output. automatic counting, no bag without filling no bag no seal

Weighting machine function is automatically check the weight of finished facial mask sand reject the un qualifed facial mask.

Facial mask bag counting and stacking machine function is machine count the inline outfeed facial mask bags, and stack them as set stacking number(5-20pcs)and then push out the stacked bags.

Our Advantage

With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

Our company provides internationally top-ranking professional project installation experience and management experience.

Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Company Profile

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Company Profile

Packing & Delivery

Cooperative Client

Our Service:

The delivery date is only 30 days

Customized plan according to requirements

Upport video inspection factory

Equipment warranty for two year

Provide equipment operation video s

Upport video inspect the finished product

Material Certificate

Contact Person

Ms Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: https://www.sinaekatogroup.com