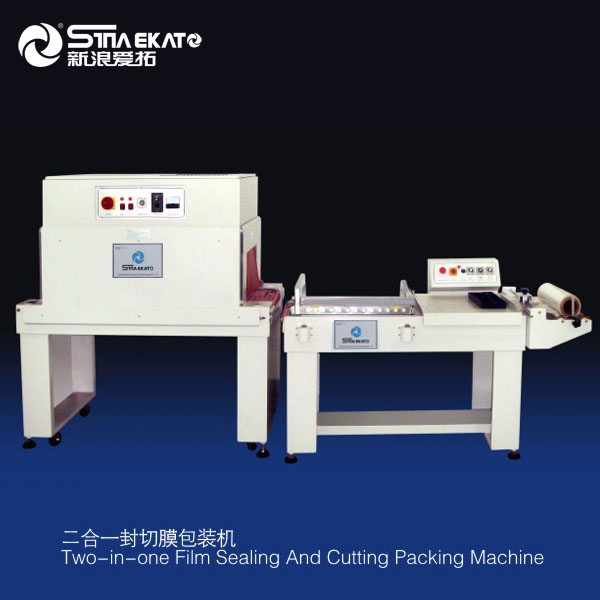

Semi Automatic Cutting Sealing Shrinking Seal Wrapping Machine 2 In 1 Wrapper

Showroom Video

Product Description

The cutting and sealing machine is generally used as a supporting equipment for the shrink packaging machine, and it can also be used alone; Teflon coated non-stick layer sealing cloth, sealing and cutting non-sticky film, and the sealing is neat and not cracked. After the product is sealed and cut, it enters the shrinking machine to complete the packaging

Features

1. Compact construction, high efficiency;

2. The use of steel heating tube prolong the life

3. Strong air-flow ensures excellent heat distribution for an even shrinking;

4. Intelligent temperature controller makes the operation easily

5. The speed of the conveyor is adjustable.

| item | sealing and cutting machine |

| ltem No. | 450L |

| Power supply | 220V 50/60HZ |

| Motor power | 1KW |

| Transfer speed | 0-15 PCS/min |

| Maximum sealing and cutting size | 450*350*200mm |

| Total Weight | 40-50KG |

| Dimension | 1080x720x910mm |

| Applicable shrink film | POF/PVC/PP |

| Remarks: | |

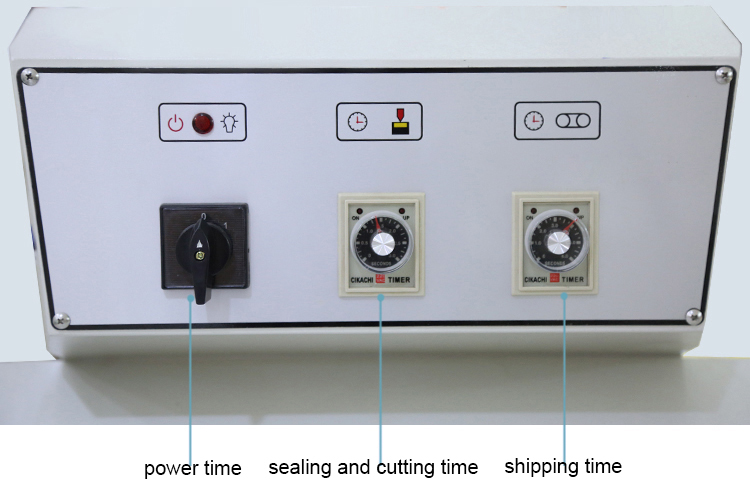

01. The panel is concise and clear, very simple and convenient for workers to operate.

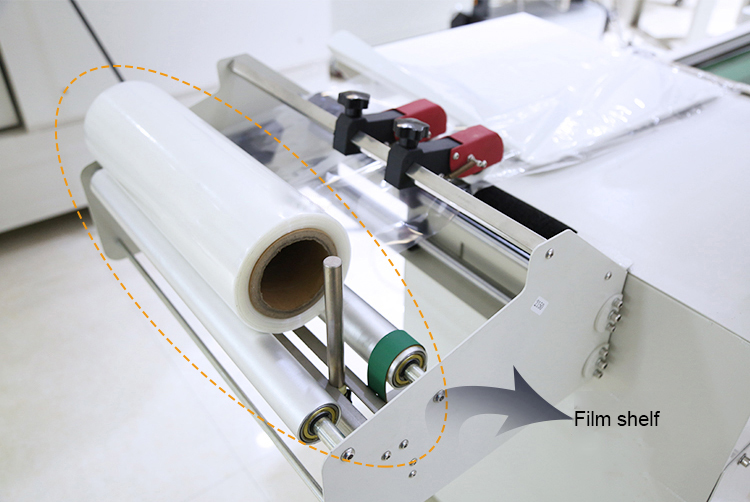

02. The film frame of the roller is thicker, the load-bearing capacity is strong, the length can be adjusted, and the film change is simple.

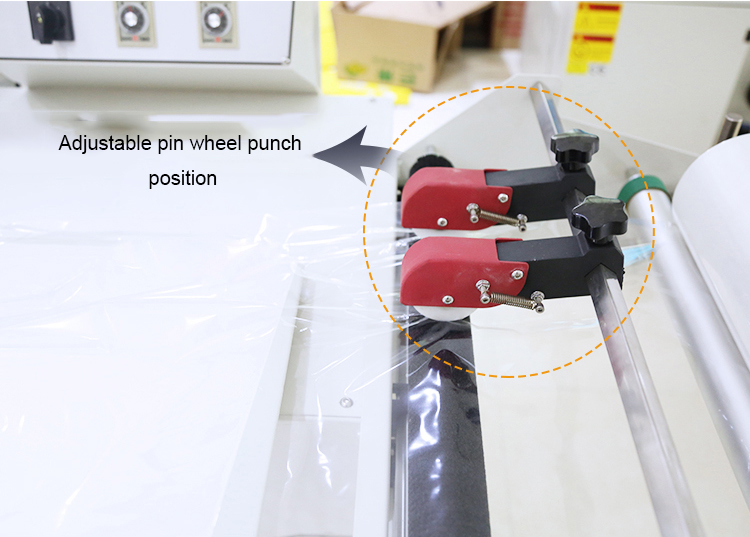

03. The pin wheel can move left and right, so that you can choose the punch position, which is very practical.

04. The sealing knife adopts Teflon-coated anti-sticking and high-temperature aluminum alloy knife, which has a firm sealing, no cracking, no coking, no smoking, and no pollution to the environment.

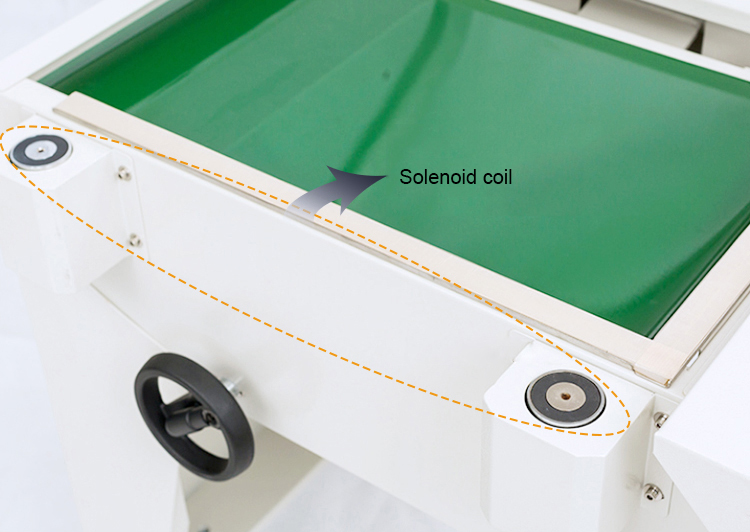

05. Pull the pull-down rod, the 2 solenoid coils are attracted and fixed for heat sealing and cutting, which is very firm.

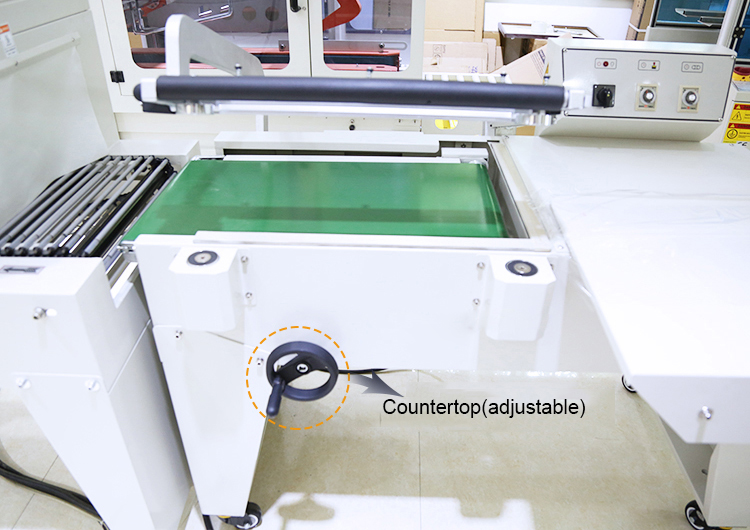

06. Turn the hand wheel according to the height of the product to adjust the height of the table.

Specification

| No. | Material volume (t) |

Unit disposing capacity(t/h) |

Initial temperature (℃) |

Final temperature (℃) |

Temperature drop difference(℃) |

Calculated cold load(kw) |

Affluence factor (1.30) |

Designed cooling capacity(kw) |

| 1 | 1.00 | 1.00 | 80.00 | 30.00 | 50.00 | 58.15 | 1.30 | 1.30 |

| 2 | 2.00 | 2.00 | 80.00 | 30.00 | 50.00 | 116.30 | 1.30 | 1.30 |

| 3 | 3.00 | 3.00 | 80.00 | 30.00 | 50.00 | 174.45 | 1.30 | 1.30 |

| 4 | 4.00 | 4.00 | 80.00 | 30.00 | 50.00 | 232.60 | 1.30 | 1.30 |

| 5 | 5.00 | 5.00 | 80.00 | 30.00 | 50.00 | 290.75 | 1.30 | 1.30 |

Advantages

1/ Advanced internal circulation system design, high shrinkage effect, low energy consumption.

2/ Stainless steel heating tube.

long service time.

3/ Movable drum transmission (can be changed to network), adjustable speed.

4/ Suitable for PVC/PP/POF film thermal shrinkage.

Exhibitions & Customers visit factory