PME-4000L Liquid Shampoo Detergent Cleanser Making Machine Liquid Washing Homogenizer Mixer

Machine Video

Application

Mixer is suitable for the production of various types of detergents cosmetics

spices and other fine chemicals necessary equipment

Performance & Features

1. The PME-4000L Mixer adopts fixed pot body, pot cover and pot body with flange connection can not be lifted.

1.2The diversified high-speed homogenizer can powerfully mix solid and liquid raw materials and can rapidly dissolve many indissoluble materials such as AES, AESA, LSA, etc.during the liquid detergent production process so as to save energy consumption and shorten production period.

2. The Mixer pot is made of three-layer stainless steel welding, the inner layer in direct contact with the material is made of imported SUS316L stainless steel, the middle jacket layer and the external thermal insulation layer are made of 304 stainless steel, and the tank body and pipeline are mirror-polished or matte, which fully meets the GMP requirements.

3. The stirring system adopts double-direction wall scraping mixing and frequency conversion speed adjustment, so as to satisfy product of different technological requirements

4. The machine adopts the bottom external circulation homogenizing system, the homogenizing motor adopts Germany Siemens, and adjusts the homogenizing machine speed through the PLC control Siemens inverter in the electric cabinet, and the homogenizing speed is 0-2880r/min

5. The machine is controlled by an independent PLC electronic control cabinet, the cabinet is made of imported stainless steel materials, the electrical components are made of Germany Schneider Electric, the inverter and PLC are made of Germany Siemens, the instrument is Omron, and the operation equipment can be monitored through the Siemens PLC touch screen equipment. And through the Siemens touch screen of the cabinet to control the stirring speed, homogenization speed, temperature control and other

Technical Parameter

| Model | PME-4000L | |

| Working Volume | 4000L | |

| Design Volume | 5000L | |

| Homogenizer Motor | Power(KW) | 30KW |

| Rotate speed(r/min) | 0-3000 r/min | |

| Stir Motor (external Mixing) | Power(KW) | 7.5KW |

| Rotate speed(r/min) | 0-60r/min | |

| Stir Motor (internal Mixing) | Power(KW) | 15KW |

| Rotate speed(r/min) | 0-30r/min | |

| Overall Dimension(L*W*H) unit(mm) | 2300*2300* | |

| Type of Heating | Steam heating | |

| Note: in case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail. | ||

Product Details

The Mixer pot is made of three-layer stainless steel welding, the inner layer in direct contact with the material is made of imported SUS316L stainless steel, the middle jacket layer and the external thermal insulation layer are made of 304 stainless steel, and the tank body and pipeline are mirror-polished or matte, which fully meets the GMP requirements.

Top Mixing System

The Mixing system of the main pot adopts bi-directional wall-scraping stirring, and the stirring motor uses a German Siemens motor to provide efficient mixing and ensure thorough blending of ingredients in the main pot.

The PME-4000L Mixer system includes a 4000L liquid washing homogenizing mixer, an independent PLC controlled electric cabinet, a piping system, a CG-8000L stainless steel storage tank, an electric lifting platform, a stainless steel platform with safety railings and steps

PME-4000L Mixer element

Cover Element

The advantages of a single-side open lid liquid washing homogenizing mixing pot include:

Material addition: The single-side open lid facilitates the addition of ingredients or raw materials during the mixing process, allowing for flexibility and control over the formulation.

Maintenance and cleaning: Cleaning and maintenance tasks can be easier with a single-side open lid, as it provides ample access to the internal components of the mixing pot.

Accessibility for equipment: It may be easier to install and remove mixing tools and equipment from the pot with a single-side open lid, improving efficiency during setup and changeover.

Bottom Homogenizer system

The main features and functions of the bottom outer circulation homogenizer include:

Efficient Blending: The homogenizer is designed to facilitate the efficient blending of ingredients, ensuring consistent product quality.

Homogenization: It is capable of breaking down and dispersing particles or droplets within the liquid, resulting in a uniform and stable product.

High Shear Mixing: The equipment is often capable of providing high shear forces to effectively mix and emulsify different substances.

Versatility: Bottom outside circulation homogenizers can be used for a wide range of applications, including mixing liquids, suspensions, and emulsions.

Controllable Parameters: They may offer control over factors such as mixing speed, circulation flow, and shear force to optimize the mixing process.

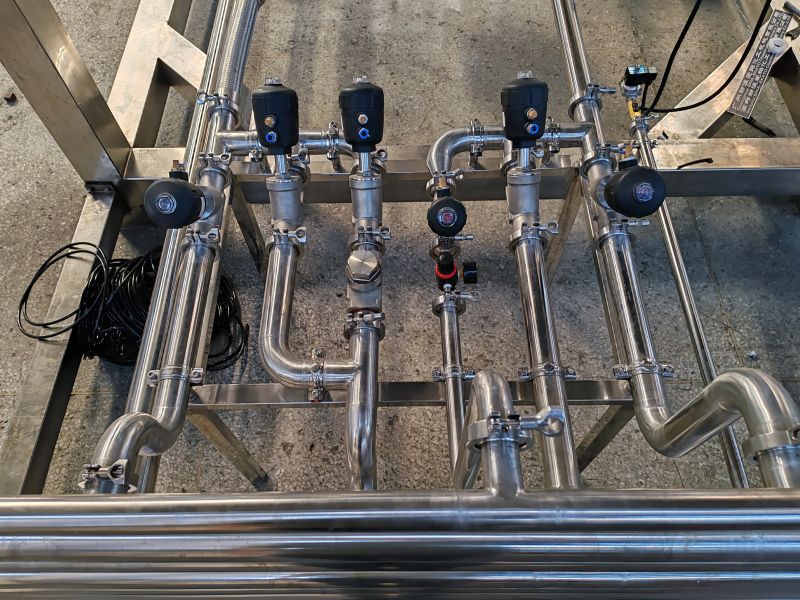

Pipe System

Sewage Pipe: This pipe is used to transport wastewater or liquid waste away from the mixer to a suitable disposal or treatment system.

Steam Inlet Pipe: This pipe is responsible for delivering steam into the mixer. Steam can be used for heating and sterilizing the liquid within the mixer.

Cooling Water Inlet Pipe: This pipe provides a flow of cooling water into the mixer to regulate the temperature of the liquid during the mixing process, preventing overheating.

Compressed Air Pipe: This pipe supplies compressed air to the mixer, which may be used for agitation, aeration, or other processes within the mixing chamber.

Steam Outlet Pipe: This pipe is responsible for releasing the steam from the mixer after it has been used in the process.

Cooling Water Outlet Pipe: This pipe is used to remove the cooling water from the mixer after it has served its purpose in regulating the temperature of the liquid.

Independent control electrical cabinet

The liquid washing homogenized mixing pot's independent control cabinet is equipped with high-quality components, including a Siemens PLC touch screen and control system, as well as electrical components from Germany Schneider. Additionally, the inverter from Germany Siemens allows for precise control over the speed of the mixing motor and the homogenized motor. This level of control ensures efficient and accurate operation of the mixing process, allowing for precise adjustments to achieve the desired mixing and homogenizing results.

The use of a PLC touch screen for controlling a liquid washing mixing pot offers several advantages. Some of these include:

User-friendly interface: The touch screen provides an intuitive and user-friendly interface for operators to control and monitor the mixing process. This simplifies operation and reduces the need for extensive training.

Precise control: The PLC (Programmable Logic Controller) offers precise control over parameters such as mixing speed, temperature, and timing. This enables fine-tuning of the mixing process to achieve the desired results and ensures consistency in product quality.

Automation capabilities: The PLC touch screen allows for automation of various mixing sequences and processes, reducing the need for manual intervention and improving overall efficiency.

Data monitoring and recording: The system can record and display important process data, such as mixing parameters, temperatures, and time durations, allowing operators to monitor and analyze the process in real time.

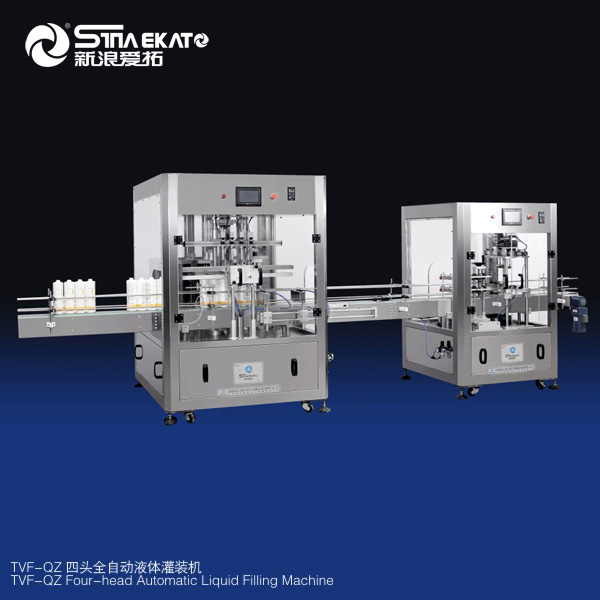

Related machinery

RO Treatment Water System

Auto Washing Bottle machine

Bottle drying machine

Sterile storage tank

Auto Liquid filling machines

Auto labeling machine

Company Profile

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Our Advantage

1. With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

2. Our company provides internationally top-ranking professional project installation experience and management experience.

3. Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

4. We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Project Production

Focus on quality other than quantity certifications

Belgium

Saudi Arabia

South Africa

Material Sources

80% of the main parts of our products are provided by world’s famous suppliers. During long-term cooperation and exchange with them, we have accumulated much valuable experience,so that we can provide customers with high quality products and more effective guarantee

Cooperative Client

Our Service

* The delivery date is only 30~60 days

* Customized plan according to requirements

* Support video inspection factory

* Equipment warranty for two year

* Provide equipment operation video

* Support video inspect the finished product

Packaging & Shipping

Material Certificate

Contact Person

Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: https://www.sinaekatogroup.com