In the manufacturing industry, especially in the production of liquid products such as detergent, shampoo, and shower gel, having the right equipment is crucial to ensure the quality and efficiency of the manufacturing process. One essential piece of equipment for this type of production is a liquid washing homogenizer mixer.

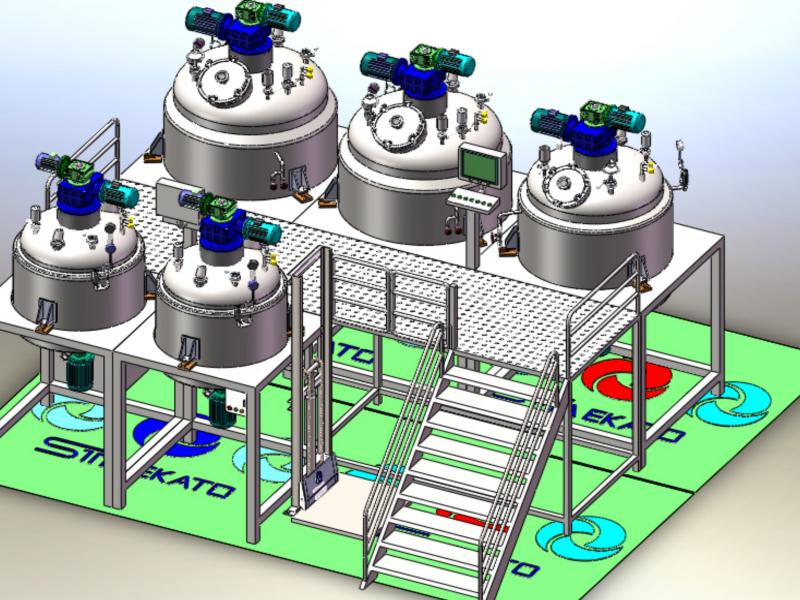

This unit is designed to integrate mixing, homogenizing, heating, cooling, and pump discharging of finished products. It plays a vital role in the production process, allowing for the creation of high-quality liquid products that meet the standards and requirements of customers and regulatory agencies.

The liquid washing homogenizer mixer is equipped with all-round wall scraping mixing technology, which utilizes a frequency converter for speed adjustment. This feature allows for the production of high-quality products with different processes according to customer requirements. Whether it’s the precise mixing of ingredients, homogenizing the mixture, or controlling the heating and cooling processes, this unit can handle it all with accuracy and efficiency.

One of the key components of the liquid washing homogenizer mixer is the high-speed homogenizer. This component is designed to powerfully mix solid and liquid raw materials, as well as rapidly dissolve many indissoluble materials such as AES, AESA, and LSA during the liquid detergent production process. This capability not only saves energy consumption but also shortens the production period, making the manufacturing process more efficient and cost-effective.

When it comes to manufacturing liquid products, especially those that are used for personal hygiene and cleaning, the quality and consistency of the final products are of utmost importance. The liquid washing homogenizer mixer ensures that the products meet the required standards by providing a thorough and uniform mixing process, as well as the homogenization of the ingredients to create a smooth and stable finished product.

Furthermore, the liquid washing homogenizer mixer is capable of pump discharging the finished products, making the transfer of the final products to storage or packaging facilities seamless and convenient. This integration of functions streamlines the production process and eliminates the need for additional equipment, saving both time and resources for the manufacturer.

In conclusion, the liquid washing homogenizer mixer is an essential piece of equipment for the manufacturing of liquid products such as detergent, shampoo, and shower gel. Its ability to integrate mixing, homogenizing, heating, cooling, and pump discharging of finished products makes it a valuable asset for any production facility. With its advanced technology and versatile capabilities, it ensures the production of high-quality liquid products while optimizing the manufacturing process for efficiency and cost-effectiveness.

Post time: Mar-01-2024