In the world of perfume creation, efficiency and precision are of the utmost importance. The SINA EKATO XS perfume making machine is a cutting-edge solution for perfume production lines, standing out by combining advanced technology with a user-friendly design. This innovative machine is designed to simplify the perfume making process, ensuring that every batch of perfume meets the highest standards of quality and consistency.

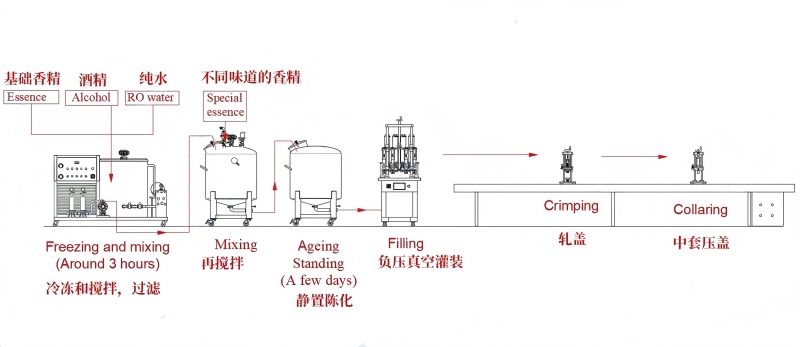

The SINA EKATO XS is a comprehensive system that includes several key components required for efficient fragrance production. At its core is a robust mixing tank designed specifically for raw materials. This tank is essential for blending the various fragrance ingredients, allowing perfumers to precisely create unique scents. The machine’s advanced design enhances the mixing process, ensuring that all ingredients are fully integrated.

One of the highlights of the SINA EKATO XS is its cooling system, which is essential for cooling the perfume mixture. Maintaining the right temperature during the production process is essential to preserve the integrity of the fragrance. Imported from well-known manufacturers such as Danfoss in France or Hitachi in Japan, this cooling unit ensures optimal cooling performance and prevents the deterioration of the raw materials.

Efficient looping and filtering

The SINA EKATO XS is equipped with a powerful circulation and discharge pump to ensure that the mixture is continuously delivered throughout the production process. The pump is a corrosion-resistant air-operated diaphragm pump imported from the United States, designed to meet the needs of perfume production while ensuring quality.

Filtration is another critical step in the perfume-making process, and the SINA EKATO XS excels in this regard. The machine uses a three-stage filtration process, using polypropylene microporous filtration membranes from the United States. This advanced filtration system effectively removes impurities, ensuring that the final product is crystal clear and free of any harmful particles.

Durability and ease of use

The SINA EKATO XS is built with premium materials to last. The stainless steel insulated freezer tank and titanium coils offer exceptional durability and corrosion resistance, making them ideal for the demanding environment of a perfume production line. In addition, the stainless steel removable stand enhances the machine’s usability, allowing the operator to easily access and manage the system.

SINA EKATO XS is designed to be user-friendly, making it easy for both experienced perfumers and newcomers to the industry to use. Intuitive controls and layout simplify operation, allowing users to focus on the creative aspects of fragrance development without being bothered by complex mechanical equipment.

in conclusion

The SINA EKATO XS perfume making machine will revolutionize perfume production lines, offering an efficient and comprehensive solution for mixing, cooling, circulating and filtering. With its high-quality components and user-friendly design, the machine not only improves the production process, but also ensures that each perfume is of the highest quality. As the perfume industry continues to evolve, the SINA EKATO XS is always at the forefront, ready to meet the needs of modern perfumers and advance the art of scent creation.

Post time: Apr-16-2025