At SinaEkato, we have been at the forefront of cosmetic machinery manufacturing since the 1990s, providing innovative solutions to a wide range of industries. Our commitment to quality and excellence has made us a trusted partner for companies looking to increase their production capabilities. Today, we are pleased to introduce our latest innovation: the new 200L Vacuum Homogenizer.

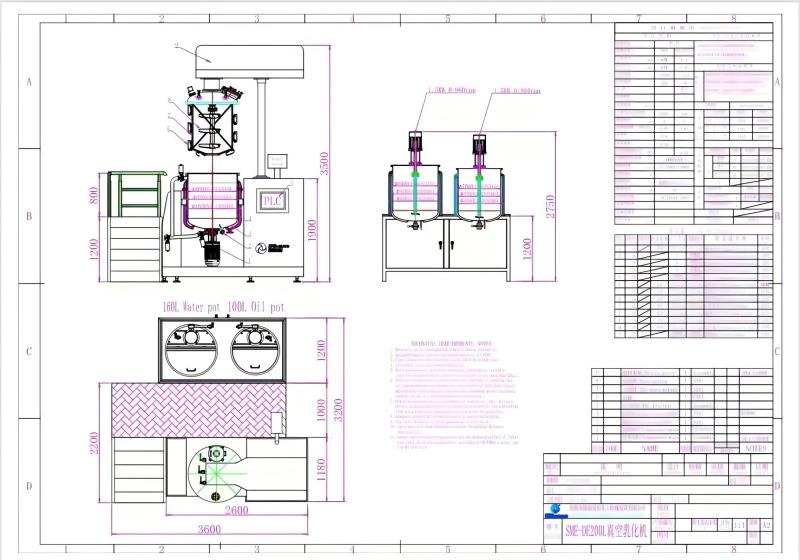

The new 200L Vacuum Homogenizer is designed for the cosmetics and personal care industry to meet the diverse production needs of creams, lotions, skin care products, shampoos, conditioners, shower gels, perfumes and even toothpaste. This state-of-the-art equipment combines advanced technology with user-friendly features to ensure your production process is efficient, hygienic and in line with the highest industry standards.

A highlight of our new homogenizer is the integrated Siemens motor and frequency converter, which enables precise speed regulation. This flexibility allows manufacturers to tailor the mixing process to specific technical requirements, ensuring the best results for a wide range of formulations. Whether you are producing thick creams or light lotions, the new 200L model can meet your needs.

Hygiene is a top priority in the cosmetics industry, and our vacuum defoaming systems address this issue head-on. By creating a vacuum environment, the agitator effectively removes air bubbles from the material, ensuring that the final product is not only aesthetically pleasing but also meets sterility standards. This feature is especially beneficial for sensitive formulations that require high purity.

In addition to the vacuum function, the new 200L is also equipped with a vacuum material suction system to minimize dust contamination, especially for powder products. This innovative design ensures that your ingredients remain uncontaminated throughout the mixing process, resulting in a higher quality end product.

The construction of the new 200L reflects our commitment to quality and compliance with Good Manufacturing Practices (GMP). The tank and pipes are carefully crafted with mirror polish, with smooth surfaces for easy cleaning and maintenance. In addition, all material contact parts are made of SUS316L stainless steel, a high-quality stainless steel known for its corrosion resistance and durability. This ensures that your equipment not only meets regulatory standards, but also withstands the test of demanding production environments.

At SinaEkato, we understand that every production line is unique. That’s why our new 200L Vacuum Homogenizer is designed with versatility in mind. Whether you’re expanding your production or launching a new product line, this mixer is the perfect solution to enhance your manufacturing capabilities.

All in all, the new 200L Vacuum Homogenizer is a game-changer for cosmetic manufacturers looking to improve their production processes. With its advanced features, hygienic design, and compliance with industry standards, this mixer will improve your product quality and efficiency. Join SinaEkato as we continue to innovate and support you on your journey in the cosmetics industry. Experience the difference of our new 200L Vacuum Homogenizer today!

Post time: Feb-26-2025