In the ever-evolving manufacturing industry, especially in the cosmetics and pharmaceutical industries, there is a surge in demand for high-quality emulsifiers. One of the latest innovations is the new 500-liter vacuum homogenizer, an advanced machine designed to meet the stringent requirements of cream, paste, lotion, mask and ointment production. This advanced mixer incorporates cutting-edge technology from Europe, especially Germany and Italy, ensuring it meets the highest efficiency and quality standards.

Introduction to 500L Vacuum Homogenizing Emulsifying Mixer

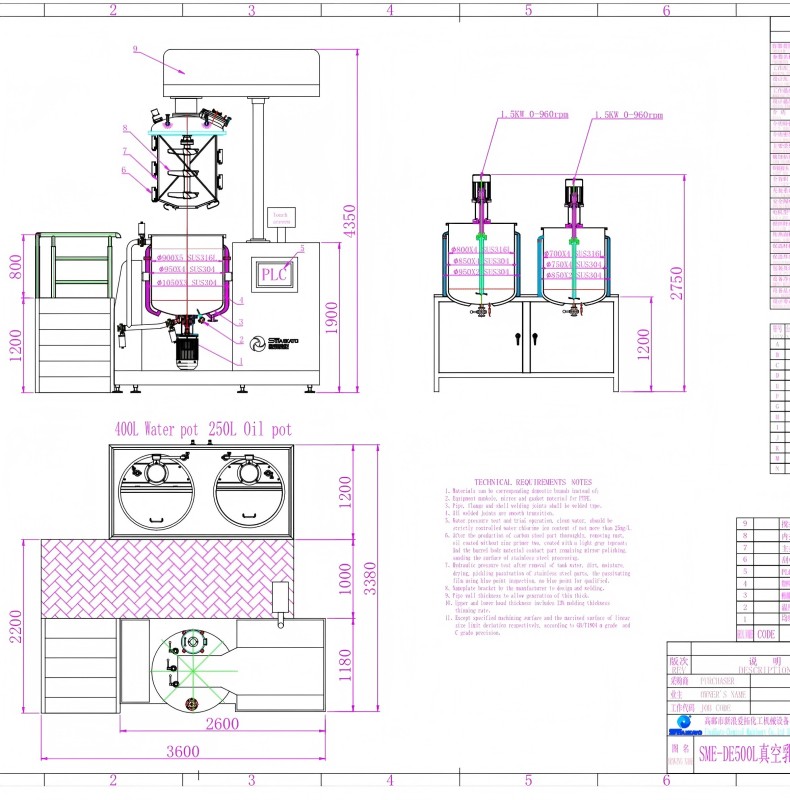

The new 500L Vacuum Emulsifier Mixer is a rugged, versatile piece of equipment that plays a vital role in the production of a wide range of cosmetics and pharmaceuticals. It is carefully designed to help produce stable emulsions, which is essential for products such as creams and lotions that require a perfect blend of oil and water. The mixer’s vacuum function not only enhances the emulsification process, but also minimizes the ingress of air, which can affect the quality and shelf life of the final product.

The mixer is equipped with advanced homogenization technology, ensuring uniform particle size distribution, thus improving product texture and performance. The integration of vacuum technology eliminates air bubbles during the mixing process, resulting in a denser and more stable emulsion. This is particularly important in the production of facial masks and ointments, where consistency and stability are crucial.

The role and use of emulsifiers

The new 500L Vacuum Homogenizer does much more than just mix. It covers a range of key processes required to produce high-quality cosmetics and pharmaceuticals. Here are some of its key features:

1. **Homogenization**: The blender uses high shear homogenization technology to break up the particles in the mixture and form a fine and uniform emulsion. This is essential to obtain the desired texture and consistency of creams and lotions.

2. **Vacuum Operation**: The vacuum system can effectively remove air from the mixture to prevent oxidation and ensure that the final product maintains its quality for a long time. This feature is especially beneficial for sensitive formulas that are easily affected by air.

3. **Temperature Control**: The blender is equipped with a temperature control function, which allows manufacturers to heat or cool the mixture as needed during the emulsification process. This is essential for certain formulations that require specific temperature conditions to achieve the best results.

4. **Versatility**: The 500-liter capacity makes this mixer suitable for both small- and large-scale production. It can handle a wide range of formulations from thick pastes to light lotions, making it a valuable asset for manufacturers looking to diversify their product offerings.

5. **User-friendly interface**: This blender is equipped with an intuitive control panel, allowing operators to easily adjust settings and monitor the blending process. This improves operational efficiency and reduces the possibility of human error.

All in all, the new 500L Vacuum Homogenizer represents a significant advancement in emulsification technology. It combines vacuum operation, high shear homogenization and temperature control in one unit, making it an essential tool for manufacturers in the cosmetics and pharmaceutical industries. By investing in this innovative equipment, companies can ensure the production of high-quality, stable emulsified products that meet the demands of today’s discerning consumers.

Post time: Apr-12-2025