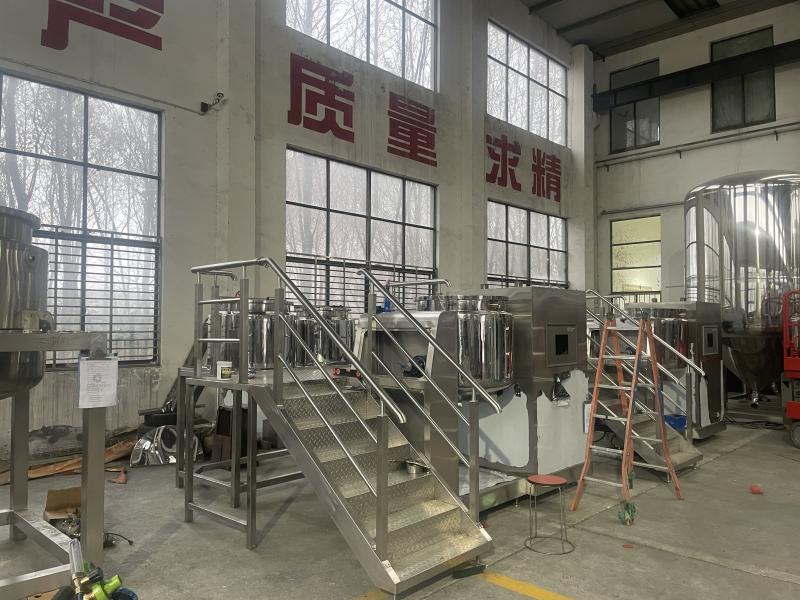

In March 2024, the production situation at SINA EKATO factory was bustling with activity as the company continued to innovate and manufacture top-of-the-line cosmetic equipment. One of the key products in focus was the vacuum homogenizing emulsifying mixer, which includes the main pot for the vacuum homogenizing emulsification mixer. This product is a perfect example of the high-quality and technologically advanced equipment that SINA EKATO is known for.

SINA EKATO is a leading cosmetic equipment manufacturing company with over 30 years of experience in the industry. The company has built a strong reputation for providing innovative and reliable products to its clients, and the vacuum homogenizing emulsifying mixer is no exception. The main pot for the vacuum homogenizing emulsification mixer is designed to meet the specific needs of cosmetic production, making it an essential piece of equipment for businesses in the industry.

The 300L vacuum homogenizing emulsifying mixer is a versatile and efficient machine that is ideal for the production of a wide range of cosmetic products. Its main pot, designed for the vacuum homogenizing emulsification mixer, allows for effective emulsification, homogenization, and mixing under vacuum conditions. This helps to ensure the quality and stability of the final product, making it ideal for the production of creams, lotions, and other cosmetic formulations. The main pot’s design and capacity make it suitable for large-scale production, catering to the needs of both small and large cosmetic manufacturers.

In March 2024, SINA EKATO’s factory was running at full capacity to meet the growing demand for the 300L vacuum homogenizing emulsifying mixer. The company’s commitment to excellence and customer satisfaction was evident in the rigorous quality control measures and efficient production processes that were in place. Each main pot for the vacuum homogenizing emulsification mixer was meticulously inspected and tested to ensure that it met the highest standards of performance and reliability.

The success of the vacuum homogenizing emulsifying mixer and its main pot can be attributed to SINA EKATO’s dedication to research and development. The company invests heavily in technology and innovation to stay ahead of the competition, and this is evident in the advanced features and capabilities of their products. With a team of experienced engineers and technicians, SINA EKATO is able to continuously improve and optimize its equipment to meet the evolving needs of the cosmetic industry.

In conclusion, SINA EKATO’s production situation in March 2024 was a testament to the company’s commitment to excellence and innovation. The 300L vacuum homogenizing emulsifying mixer and its main pot for the vacuum homogenizing emulsification mixer are prime examples of SINA EKATO’s dedication to providing high-quality, reliable, and efficient cosmetic equipment. As the demand for these products continues to grow, SINA EKATO is poised to maintain its position as a leader in the industry, setting the standard for excellence in cosmetic equipment manufacturing.

Post time: Mar-05-2024