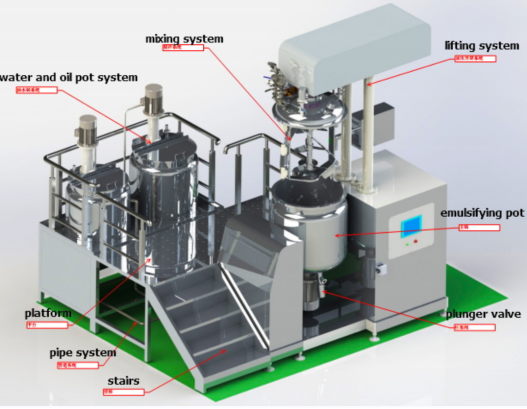

In the world of industrial mixing and emulsification, new vacuum homogenizers have become game-changers, offering cutting-edge technology and unparalleled efficiency. This innovative mixer is designed to meet the diverse needs of industries ranging from cosmetics and pharmaceuticals to food and beverage production. With its advanced features and state-of-the-art design, the new vacuum homogenizer will redefine the standards in emulsification technology.

One of the main highlights of the new vacuum homogenizer is its three-layer stainless steel construction. This sturdy construction ensures durability and hygiene, making it suitable for handling a wide range of products. All parts in contact with the product are made of stainless steel 316L, and other surfaces are made of stainless steel 304, further enhancing its corrosion resistance and service life, meeting the highest industry quality and safety standards.

Versatility is another hallmark of this cutting-edge blender, as it offers both electric and steam heating options. This dual heating feature gives users the flexibility to choose the most suitable heating method based on their specific production requirements, ensuring optimal results and energy efficiency.

The new vacuum homogeneous mixer is equipped with a unique mixing mechanism that distinguishes it from traditional mixers. It features two different mixing directions, combined with spatula and spiral mixing, to mix ingredients thoroughly and evenly. This innovative approach ensures that even the most challenging formulations are completely homogeneous and meet the stringent quality standards required by modern industry.

In addition, the bottom homogenizer with circulation function enhances the emulsification performance of the mixer, which can effectively disperse immiscible liquids and form a stable emulsion. This feature is particularly beneficial for industries such as cosmetics and pharmaceuticals, where precise and consistent emulsification of ingredients is critical to product quality.

The new vacuum homogenizer is designed for seamless operation and control, with a user-friendly interface including a touch screen and PLC system. This intuitive control system precisely regulates the mixing process, ensuring repeatable and consistent product quality. In addition, all mixing motors adopt German Siemens, which is famous for its reliability and performance, further improving the operating efficiency and service life of the mixer.

In summary, the new vacuum homogenizer represents a significant advancement in emulsification technology, providing a comprehensive solution for industries seeking superior mixing and homogenizing capabilities. With its sturdy stainless steel construction, versatile heating options, innovative mixing mechanism and advanced control system, this blender promises to raise the bar for emulsification technology in every field. Whether in the production of cosmetics, pharmaceuticals or food and beverages, the new vacuum homogenizer will become the first choice to achieve excellent emulsification effects.

Post time: May-09-2024