GZF-F 45-60Pcs/Min China Best Model Soft Toothpaste Tube Plastic Composite Cosmetic Tube Filling Sealing Machine

Machine Video

Application

Features

Speed: 45-60 Pcs/Min for 100ml tube;

Hot air moved by piston instead of cam;

Technical characters:

1. High grade operation screen with LCD display and PLC control, easy operation and more humanization By stepless speed adjust, parameter set, output count, pressure index and failure display.

2. Automatically executing tube supply,photocell register, inert gas filling (optiona1), material filling and sealing, batch number printing, final products output.

3. High prevision photocell register, that reduces the chromatic aberration scope.

4. Adjustment parts external in position, position digital display, convenient and accurate adjust (suitable for variable products producing).

5. Mechanical, photoecectrical, electric, pneumatic integrative controlling, reaches no tube no filing function: warning if tube error positioned or pressure too 10w, it will automatic stop while open the protective door.

Technical parameters

| Product | Automatic Tube Filling And Sealing Machine |

| Total Power | 2Kw 380V/220V 50Hz |

| Heat sealing power | 3Kw |

| Tube material | Plastic Tube, Laminate Tube |

| Tube diameter(ram) | φ10-φ60 |

| Tube length(mm) | 50-300 (customizable) |

| Filling volume | 5-800ml/pcs (Adjustable) |

| Filling accuracy | ≤±1% |

| Speed(r/min) | 2.5-7 |

| Product capacity(pc/min) | 30-60 (Adjustable) |

| Air supply | 0.55-0.65Mpa 0.1 m 3 /min |

| Overall dimension | 2620×1020×1980mm |

| Machine weight | 1100kg |

| Certificate | CE ISO |

| Warranty | 1 Year |

Description:

The machine with safety device. No tube no filling, with overload protection provided Artificial feeding tubes → Auto Tube orientation → Auto Filling → Auto sealing →Auto producing date printing → Auto trimming →Auto tubes output;

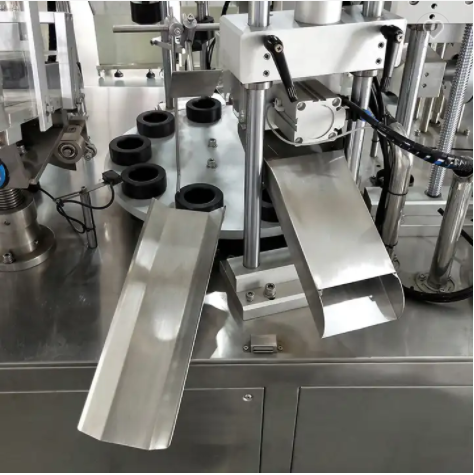

Details Part

GZF-F model full automatic composite tube filling and sealing machine, is mainly applied to filling and sealing of the container with aluminum tube as packing materials. Paste and liquid is filled by enclosed and semi-enclosed way, no leakage sealing;

AUTO TUBE LOADER

A tube loader contains a loader and a tunnel. When tubes are put in the loader, they will be conveyed automatically to the working disk by the tunnel.

ROTARY FILLING SYSTEM

Suitable for viscous product.

FILLING SEALING SYSTEM

STEP1: Automatically put tubes into the molds on the plate (12 points);

STEP2: Tubes point located by the device (color sensor optional);

STEP3: Start filling when the tube is sensed by the light;

STEP4: 4 folds sealing1 and output finished products;

Relevant Machines

Cartoning Machine

GZF-S Semi-auto Cream Lotion Toothpaste Hair-dye Gel Tube Filling and Sealing Machine (Works for Plastic & Laminated & Aluminum Tube)

Exhibitions & Customers visit factory