Color Cosmetic Vacuum Dispersing Mixer Hydraulic PLC Control

Machine Testing Video

Prodcut Display

Technical Sheet

|

item |

value |

|

Mixer Type |

Single direction mixing Two directions mixing Dispersing Emulsifying Homogenizer |

|

Max. Loading Capacity |

50L- 5000L |

|

Advantage |

High quality,with CE standard |

|

Material |

SUS304, SUS316L;All contact material is Stainless steel 316L |

|

Additional Capabilities |

heating and cooling |

|

Heating |

Electric or Steam Heating |

|

Top mixing |

Optional |

|

Top homogenizer |

Optional |

|

Top dispersing |

Optional |

|

Bottom homogenizer |

Optional |

|

Note: Machine can customized. |

|

Features and Advantages

● Adopting imported frequency converter for speed regulation, which can meet the production requirements of different processes;

●Using double-end mechanical seal effect, the highest emulsification speed can reach 4200 rpm, and the highest shear fineness can reach 0.2-5um;

● The pot body is composed of three-layer stainless steel plates, and the pot body and pipes are mirror-polished, which meets the requirements of GMP;

● The electrical equipment adopts imported configuration, the machine control is more stable, and the equipment meets international standards.

Application of Processing Materials

● Daily chemical and cosmetic industry: Skin care cream, shaving cream, shampoo, toothpaste, cold cream, sunscreen, facial cleanser, Nutrition honey, detergent, shampoo, etc.

● Pharmaceutical industry: Latex, emulsion, ointment, oral syrup, liquid, etc.

● Food industry: Sauce, cheese, oral liquid, nutrient liquid, baby food, chocolate, sugar, etc.

● Chemical industry: Latex, sauces, saponified products, paints, coatings, resins, adhesives, lubricants, etc.

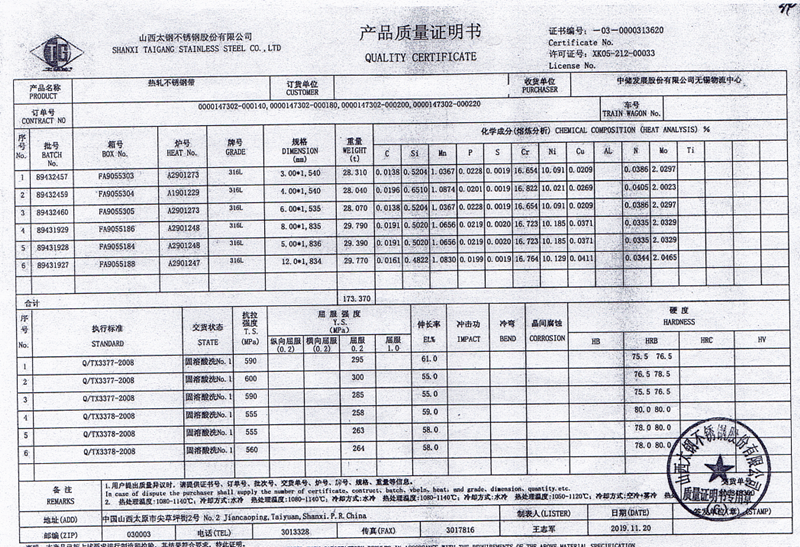

Material Testing

customers test

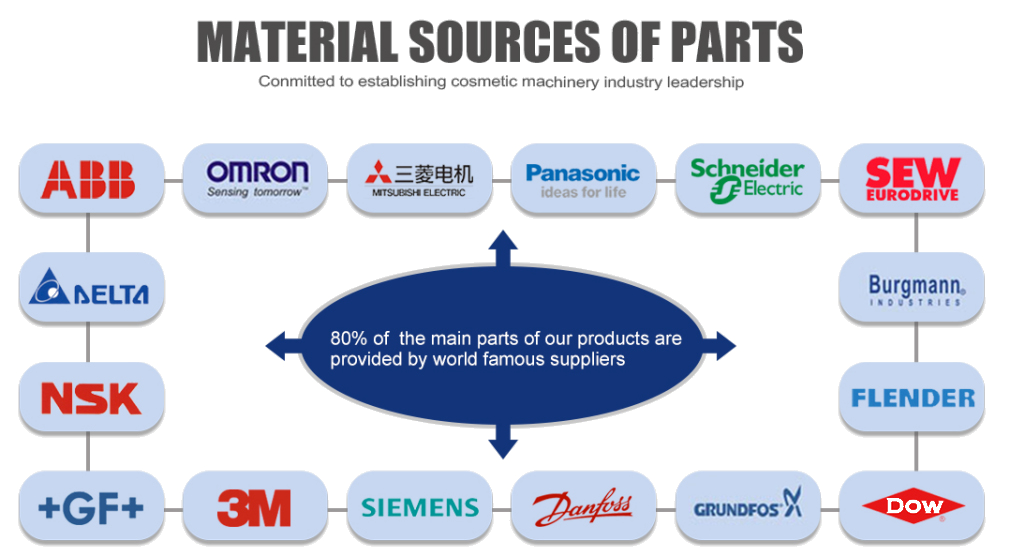

Machine Part Details

All contact material parts stainless steel 316L, middle layer & surface stainless steel 304;

1. All Mixing Motor: Germany Siemens;

2. Invert speed control: Germany Siemens;

3. Electrical component: Germany Schneider;

4. Temperature probe: PT100 + Omron display;

5. Mechanical sealing(Burgman brand ), water-cooled type;

6. Bearing- NSK from Japan.

Top Cover Elements

1. Fragrance hopper (Inlet for additional Ingredients)

Add other small amount of Ingredients (300ml capacity)

2. Vacuum gauge

It is used to observe tank internal pressure and to configure the Min and Max operation limits for vacuum operation.

3. Vacuum sensor

When it shows green light when no vacuum

4. Manhole + screw view

Improve the brightness of the pot, easy to observe the material situation.

5. Oil phase/Water phase Premixer inlet through main pot vacuum feature

Under the vacuum condition, the material will be sucked into homogenizing tank directly through the transfer pipe.

6. Air breath unit with filter cartridge

To avoid the dust particles in the air into the tank when the liquid level

lower.

7. LED Light

Improve the brightness of the pot, easy to observe the material situation.

8. Positive pressure inlet

It used for pushing thick product discharge out quickly.

Factory Production

1. Sales: Monthly sale 20Pcs Mixer;

2. Sales volume: 50L,100L, 200L, 300L, 500L, 1000L, 2000L, 3000L, 5000L;

3. Sales area: USA, France, UAE, Spain, Africa, Thailand...ect;

4. Customer satisfaction: 100% satisfaction for service quality and customer loyalty.