500L/Hour – 5000L/Hour Water Treatment Plant industrial stainless steel/PVC Reverse Osmosis Water Purification One-stage and Two-stage

description

This system occupy little space, easy to operate, wide application range.

When used for disposing industrial water, the reverse osmosis device does not consume large amounts of acids and alkalis, and there is no secondary pollution. In addition, its operation cost is also low.

Reverse osmosis desalting rate >99%, machine desalting rate >97%. 98% of organic matters, colloids and bacteria can be removed.

Finished water under good electric conductivity, one stages 10 ≤ μs/cm, two stage around 2-3 μs/cm, EDl ≤ 0.5 μs/cm (base on raw water ≤ 300 μs/cm)

High operation automation degree. It is unattended. The machine will automatically stop in case of water sufficiency and automatically start in case of no water. Timed flushing of front filtering materials by automatic controller.

Automatic flushing of reverse osmosis film by lC microcomputer controller. Online display of raw water and pure water electric conductivity.

Imported parts account for over 90%.

| Model | Capacity(T/H) | Power(K) | Recovery(%) | One-stage Finished Water Conductivity (Hs/cr) |

Two-stage Finished Water Conductivity( Hs/cm) |

EDI Finished Water Conductivity( Hs/CM) |

Raw Water Conductivity( Hs/cH) |

| R0-500 | 0.5 | 0.75 | 55-75 | ≤10 | 2-3- | ≤0.5 | ≤300 |

| R0-1000 | 1.0 | 2.2 | 55-75 | ||||

| R0-2000 | 2.0 | 4.0 | 55-75 | ||||

| R0-3000 | 3.0 | 5.5 | 55-75 | ||||

| R0-5000 | 5.0 | 7.5 | 55-75 | ||||

| R0-6000 | 6.0 | 7.5 | 55-75 | ||||

| R0-10000 | 10.0 | 11 | 55-75 | ||||

| R0-20000 | 20.0 | 15 | 55-75 |

| No | Item | Data | |

| 1 | Description | ure water treatment purifying machine | |

| 2 | Voltage | AC380V-3phase | |

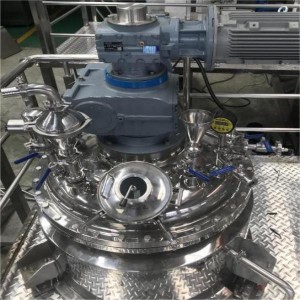

| 3 | Component | sand filter+carbon filter+soften filter+precision filter+Ro fitler | |

| 4 | Pure water production capacity | 50OL/H,500-500OL/H can be customized | |

| 5 | Filter principle | Physical filtration+reverse osmosis filtration | |

| 6 | Control | Button or PLC+Touch screen | |

Features

1. The reverse osmosis device has small volume, simple operation and wide application range.

2. Using reverse osmosis device to treat industrial water does not consume a lot of acid and alkali, and has no secondary pollution. Its operating cost is also relatively low.

3. The desalination rate of reverse osmosis is ≥ 99%, and the desalination rate of the whole machine is ≥ 97%, which can effectively remove 98% of organic matter, colloid, bacteria, etc.

4. The conductivity of produced water is good, and the first level is ≤ 10 μ S/cm, the second level is 2-3 μ S/cm, EDI ≤ 0.5 μ S/cm (raw water ≤ 300 μ s/cm)。

5. High degree of operation automation, automatic start and stop, automatic control and timing washing of the front ferry, automatic washing of the reverse osmosis membrane by IC microcomputer controller, and online display of conductivity.

6. More than 90% of imported parts.

Flowchart for Two-stage Type:

Raw water→ Raw water tank →Raw water pump→Sand filter→Carbon filter→safty filter→(high pressure pump)one stage RO→Middle water tank→(High pressure pump)two stage RO→stainless steel pure water tank→pure water pump→Using pure water point

Application

Electronic industry water: integrated circuit, silicon wafer, display tube and other electronic components;

Pharmaceutical industry water: large infusion, injection, tablets, biochemical products, equipment cleaning, etc.

Chemical industry process water:

chemical circulating water, chemical products manufacturing, etc.

Electric industry boiler feeding water:

thermal power generation boiler, low pressure boiler power system in factories and mines.

Food industry water:

purified drinking water, beverage, beer, alcohol, health products, etc.

Seawater and saline water desalination:

islands, ships, marine drilling platforms, saline water areas

Purified drinking water:

house properties, communities, enterprises, etc.

Other process water:

automobile, home appliance painting, coated glass, cosmetics, fine chemicals, etc.

Projects

UK Project - 1000L/Hour

DUBAI Project - 2000L/Hour

DUBAI Project - 3000L/Hour

SRI LANKA Project - 1000L/Hour

SYRIA PROJECT- 500L/HOUR

SOUTH AFRICA - 2000L/HOUR

KUWAIT PROJECT - 1000L/HOUR

Related products

CG-Anion Cation Mixing Bed

Ozone Generator

Current Passing Type Ultraviolet Sterilizer

CG-EDI-6000L/Hour