500-1500ml Automatic tracking Filling Machine

Machine Working Video

Product Feature

The piston fillers are designed to dispense products of different viscosity,

The components that come in contact with product are made of 316 stainless steel which is sourced from Sweden and processed by CNC machines to ensure a surface roughness lower than 0.8. Main pneumatic components are from Airtac, Taiwan. PLC & Touch screen is from Siemens.

1. Equipped with a bottle mouth localizer to make the machine suitable for different shapes of bottles including irregular bottles

2. “No drip” filling nozzle can assure that dripping and stringing will not happen.

3. This machine has functions of “no bottle no fill”, “malfunction check and malfunction scan automatically”, “security alarm system for abnormal liquid level”.

4. The parts are connected with clamps, which makes the machine easy and quick to disassemble & assemble and clean.

5. The series of machine has compact, reasonable configuration and nice, simple appearance.

6. Filling mouth with anti-drip function can be changed to lift for high foam products.

7. Material feeding device control box on the feeding, so that material is always kept at a certain range to ensure the accuracy of filling volume.

8. Rapid adjustment to achieve the overall filling volume, with counter display; the amount of each filling head can be individually fine-tuned, convenient.

9. With PLC programming control, touch-type man-machine interface, convenient parameter setting. Fault self-diagnosis function, clear failure display.

10. Filling head is an option, easy maintenance without affecting the other single head when filling.

Application

Mainly used for lubricating oils skin care products, hair washing products, body washing, hair care, body care, other washing products, sauces, oral liquids.

Cream

Lotion

Shampoo

Hair conditioner

Body wash

Mouth wash

Hand sanitizer

product parameters

| No | Description | |

| Contact material part stainless steel 316L, other part stainless steel 304; | ||

|

(Follow type + Servo type) 4 Heads Filling Machine - 4 nozzles filling machine(servo motor: 1KW); - Material tank dia76*2; - Transfer valve is direct push plunger valve, cylinder model SDA32-30; - Connecting hose (quick PVC hose); - Adopt anti-drip cylinder filling head, cylinder with blowing power; - Japan Omron reflector photoelectric counting; - No bottle lack bottle no filling; - Servo filling head lifting, touch screen to set the height of bottle mouth;

|

||

| 1 | Filling head: |

2 heads; 4 heads; 6 heads; 8 heads; 10 heads; 12heads; (Accept customized) |

|

2 |

Filling range | 5-60ML; 10-120ML; 25-250ML; 50-500ML;100-1000ML |

| 3 | Bottle height suitable range | 50-200MM |

| 4 | Bottle height suitable diameter | 40-110MM |

| 5 | Product can fill | Cream, lotion, detergent,shampoo, liquid-washing products, water... |

| 6 | Filling precision: | ±1% |

| 7 | Air Pressure: | 0.6Mpa |

| 8 | Program controller: | Touch screen & PLC |

| 9 | Filling speed: | 40-80 bottles/min |

| 10 | Working condition | Power:220V 2KW Air pressure:4-6KG |

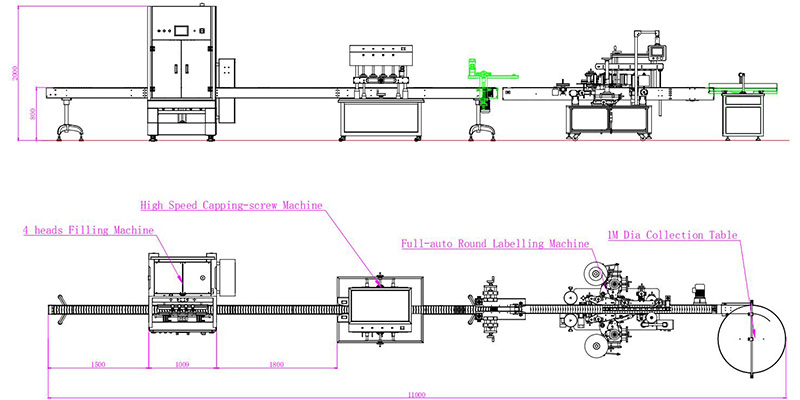

| 11 | Dimension | 5000*1300*1950mm |

Main Configuration List

| No | Name | Original |

| 1 | PLC | SIEMENS |

| 2 | Touch screen | SIEMENS |

| 3 | Servo motor(Filling) | MITSUBISHI |

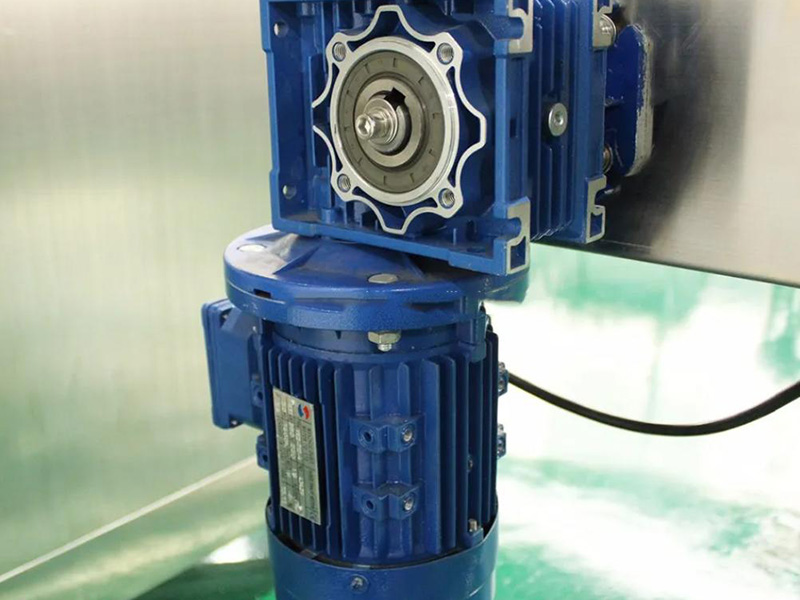

| 4 | Conveyor belt motor | JSCC |

| 5 | Alternating current contractor | Schneider |

| 6 | Emergency scenter | Schneider |

| 7 | Power Switch | Schneider |

| 8 | Buzzer | Schneider |

| 9 | Converter | MITSUBISHI |

| 10 | Filling nozzle cylinder | AirTAC |

| 11 | Rotary valve cylinder | AirTAC |

| 12 | Blocking bottle cylinder | AirTAC |

| 13 | Clamping bottle cylinder | AirTAC |

| 14 | Detection of photoelectric | OMEON |

| 15 | switch | OMEON |

| 16 | Solenoid valve | AirTAC |

| 17 | Filter | AirTAC |

Show

CE Certificate

Labeling Machine

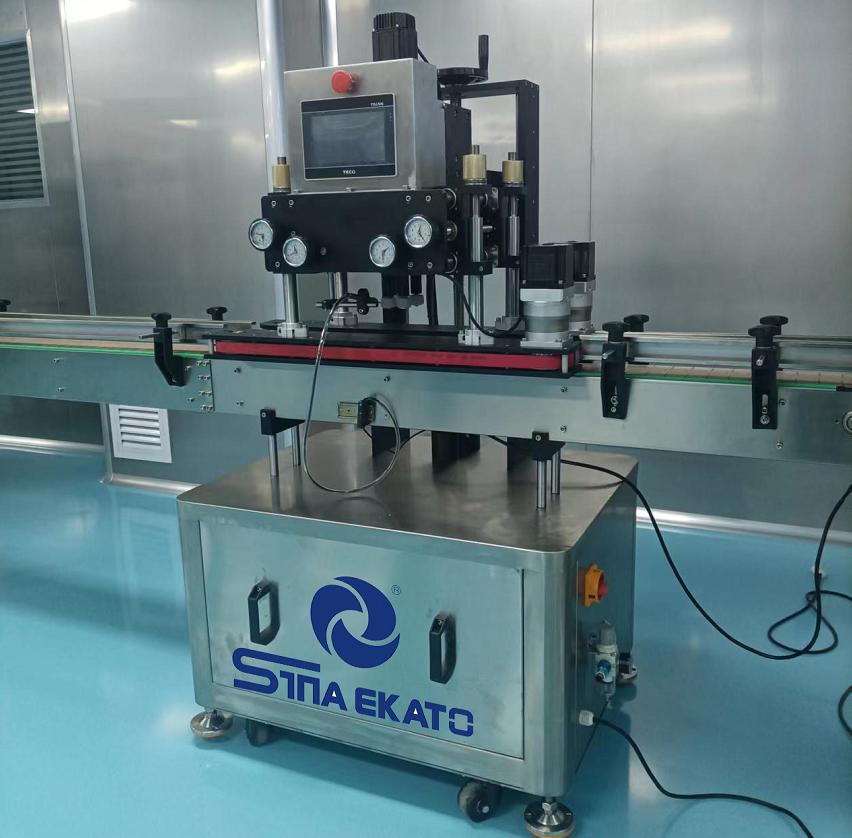

Full-auto Capping Screw Machine

Feeding Table & Collection Table

Projects

Cooperative customers