50-2000L vacuum homogenizing emulsifier can be customized foreign brand accessories

Application

SME Vacuum emulsifier is professionally designed according to the cream/paste manufacturing process, introducing advanced technology from Europe/America. The machine composed of two pre-mixing pot, vacuum emulsifying pot, vacuum pump, hydraulic system, discharge system, electric control system and working platform etc. The machine is easy operation, stable performance, perfect homogenizing performance, high work efficiency, easy for cleaning, reasonable structure, occupy small space, highly-automatized.

The customer is experimenting with face cream in the factory

Performance & Features

1.The vacuum emulsifiers produced by our company include many varieties. The homogenizing systems include top homogenization, bottom homogenization, internal and external circulating homogenization. The mixing systems include single-way mixing, double-way mixing and helical ribbon mixing.The lifting systems include single-cylinder lifting and double-cylinder lifting.Various high quality products can be customized according to customer requirements.

2.The triple mixing adopts the imported frequency converter for speed adjustment, which can meet different technological demands.

3.The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 4, 200 rpm and the highest shearing fineness can reach 0.2-5μm.

4.The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking is adopted, and especially for the powder materials, vacuum sucking can avoid dust.

5.The emulsifying pot lid can adopt lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge.

6.The pot body is welded by imported three-layer stainless steel plate.The tank body and the pipes adopt mirror polishing, which fully conforms to GMP requirements.

7.According to technological requirements, the tank body can heat or cool the materials. The heating modes mainly include steam heating or electric heating. To ensure the control of the whole machine is more stable, the electric appliances adopt imported configurations, so as to fully meet the international standards.

Technical Parameter

|

Model |

Capacity |

Homogenizer Motor |

Stir Motor |

Limit vacuum(Mpa) |

|||||

|

|

|

KW |

r/min |

KW |

r/min |

Steam heating |

Electric heating |

|

|

|

SME-DE5 |

5L |

0.37 |

3000 |

0.18 |

63 |

2 |

5 |

-0.09 |

|

|

SME-DE10 |

10L |

0.75 |

3000 |

0.37 |

63 |

3 |

6 |

-0.09 |

|

|

SME-DE50 |

50L |

3 |

3000 |

1.1 |

63 |

9 |

18 |

-0.09 |

|

|

SME-DE100 |

100L |

4 |

3000 |

1.5 |

63 |

13 |

32 |

-0.09 |

|

|

SME-DE200 |

200L |

5.5 |

3000 |

2.2 |

63 |

15 |

45 |

-0.09 |

|

|

SME-DE300 |

300L |

7.5 |

3000 |

2.2 |

63 |

18 |

49 |

-0.085 |

|

|

SME-DE500 |

500L |

11 |

3000 |

4 |

63 |

24 |

63 |

-0.08 |

|

|

SME-DE1000 |

1000L |

15 |

3000 |

5.5 |

63 |

30 |

90 |

-0.08 |

|

|

SME-DE2000 |

2000L |

15 |

3000 |

7.5 |

63 |

40 |

_ |

-0.08 |

|

Product Details

The Mixer pot is made of three-layer stainless steel welding, the inner layer in direct contact with the material is made of imported SUS316L stainless steel, the middle jacket layer and the external thermal insulation layer are made of 304 stainless steel, and the tank body and pipeline are mirror-polished or matte, which fully meets the GMP requirements.

The main pot mixing system adopts two-way wall scraping screw belt mixing, and the stirring motor adopts German Siemens motor to provide efficient mixing and ensure that the ingredients in the main pot are thoroughly mixed.

Performances and features

◆High speed rotor endows the material with high centrifugal speed and great centrifugal force. When slowing down instantaneously, the

material suffers the associative action of cavitation, detonation, shearing and grinding. Meanwhile, the material is imbibed from upside of the homogenizer and erupted from the sideward plug hole. By the

combined action of the stirrer along the vessel wall, granule spreads homogeneously and uniformly and the degree of uniformity shall come up to more than 99%.

◆Very small aperture between stator and rotor shall assure the effect of grinding, shearing, mixing and emulsifying of the material and avoid colliding and friction during the rotor rotates with high speed.

Cover Element

Performances and featy

For material of super high viscosity (above 50,000 C.P.S), the high viscosity vacuum emulsifying homogenizer is highly recommonded. Raw materials can be directly sucked into the groove by the machine. The machine is equipped with vacuum, hydraulic pressure, heating, cooling and other functions.

Emulsifying, blending and dispersion can be completed within a short period of time.

Slow speed blade type blending and high speed homogenizing systems are provided with frequency conversion control.

Users can select push button control or PLC touch screen system. Parts that contact materials are made of stainless steel SS316L.The whole equipment conforms to GMP standard.

Blending is carried out under vacuum to effectively ensure the emulsifying effect.

The machine equipped with CIP,which can convinient user's own CIP system to clean the machine.

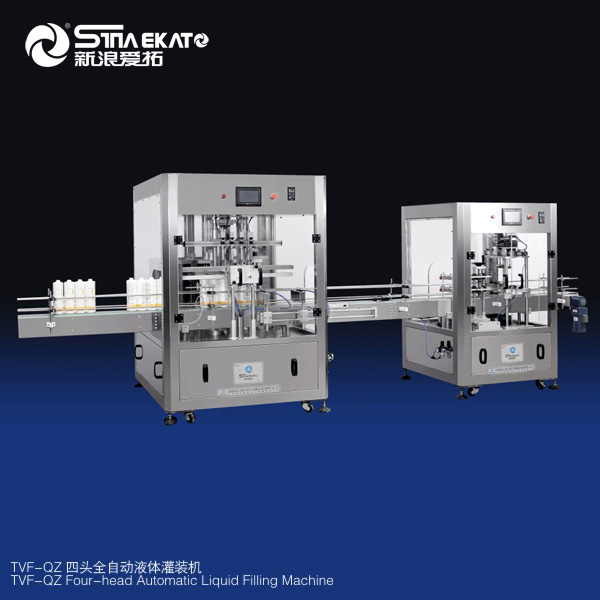

Related machinery

RO Treatment Water System

Auto Washing Bottle machine

Bottle drying machine

Sterile storage tank

Auto Liquid filling machines

Auto labeling machine

Company Profile

With the solid backing of Jiangsu Province Gaoyou City Xinlang Light

Industry Machinery & Equipment Factory, under the support of German design center and national light industry and daily chemicals research institute, and regarding senior engineers and experts as the technological core, Guangzhou SINAEKATO Chemical Machinery Co., Ltd. is a professional manufacturer of various types of cosmetic machinery and equipment and has become a brand enterprise in the daily chemical machinery industry. The products are applied in such industries as. cosmetics, medicine, food, chemical industry, electronics, etc., serving many nationally and internationally famous enterprises such as Guangzhou Houdy Group, Bawang Group, Shenzhen Lanting Technology Co., Ltd., Liangmianzhen Group, Zhongshan Perfect, Zhongshan Jiali, Guangdong Yanor, Guangdong Lafang, Beijing Dabao, Japan Shiseido, Korea Charmzone, France Shiting, USA JB, etc.

Our Advantage

1. With many years of experience in domestic and international installation, SINAEKATO has successively undertaken the integral installation of hundreds of large-sized projects.

2. Our company provides internationally top-ranking professional project installation experience and management experience.

3. Our after-sales service personnel have practical experience in equipment use and maintenance and receive systemic trainings.

4. We are sincerely providing customers from home and abroad with machinery & equipment, cosmetic raw materials, packing materials, technical consultation and other service.

Project Production

Focus on quality other than quantity certifications

Belgium

Saudi Arabia

South Africa

Material Sources

80% of the main parts of our products are provided by world’s famous suppliers. During long-term cooperation and exchange with them, we have accumulated much valuable experience,so that we can provide customers with high quality products and more effective guarantee

Cooperative Client

Our Service

* The delivery date is only 30~60 days

* Customized plan according to requirements

* Support video inspection factory

* Equipment warranty for two year

* Provide equipment operation video

* Support video inspect the finished product

Packaging & Shipping

Material Certificate

Contact Person

Jessie Ji

Mobile/What’s app/Wechat: +86 13660738457

Email: 012@sinaekato.com

Official website: https://www.sinaekatogroup.com